Lithium Ion Batteries |

您所在的位置:网站首页 › calendaring virtuoso 翻译 › Lithium Ion Batteries |

Lithium Ion Batteries

|

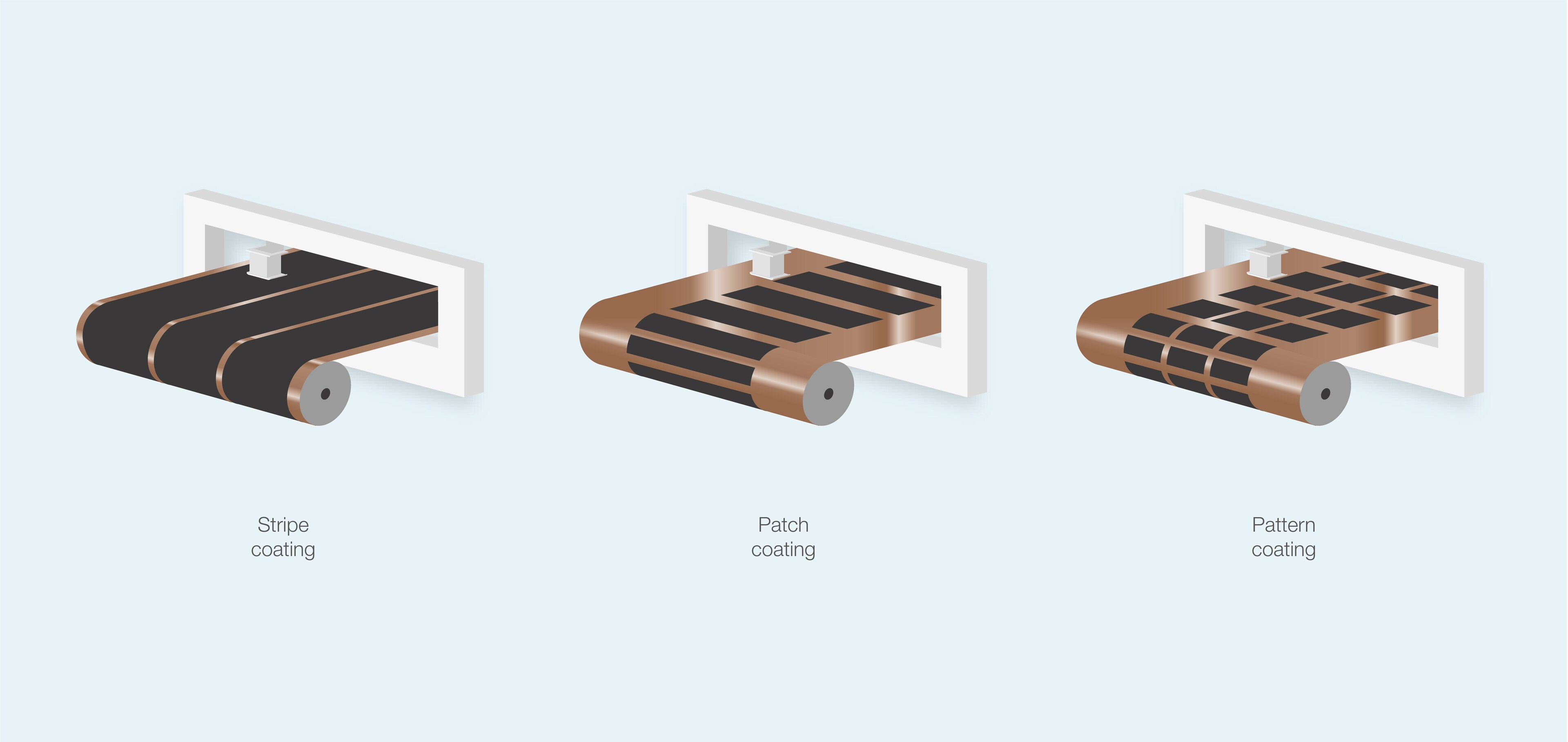

The global market for Lithium-ion (Li-ion) batteries is projected by Research and Markets to reach US$91.8 billion by 2025 driven by their use in a wide range of energy storage applications. The reports goes on to say that a major driver of growth is electric vehicles (EVs). The US. Office of Energy Efficiency & Renewable Energy explains on its website how a Lithium-ion battery works: A battery is made up of an anode, cathode, separator, electrolyte, and two current collectors (positive and negative). The anode and cathode store the lithium. The electrolyte carries positively charged lithium ions from the anode to the cathode and vice versa through the separator. The movement of the lithium ions creates free electrons in the anode which creates a charge at the positive current collector. The electrical current then flows from the current collector through a device being powered (cell phone, computer, etc.) to the negative current collector. The separator blocks the flow of electrons inside the battery. Critical to the advancement of the battery is the emergence of higher quality separator film, coating of the separator film for higher efficiency, and the uniform coating of the anode and cathode materials. The coating thickness and weight must be uniform to ensure a longer-lasting and safer battery. (We previously wrote about this subject in The Importance of Film and Coating Measurement of Lithium-Ion Batteries.) There are measurement and control systems that have been specifically designed to address the need for accurate electrode coating weight measurement, multilayer thickness measurement of separator films and electrode calendering thickness measurement. This web gauging technology can help battery producers address these three important processes involved in Lithium-ion battery manufacturing, which will help improve their safety, consistency and efficiency, and ultimately to deliver high quality, reliable products. Separator film lines. Separator film is one of the key components of a Li-ion battery. With its special thermal shutdown properties, it can help to stop thermal runaways and prevent short-circuiting, while facilitating the flow of charged ions. Separator films can be coated with materials such as ceramic to improve efficiency and safety. Anode and cathode coating lines. Continuous stripe, patch or pattern coating on an aluminum (Cathode) or copper (Anode) substrate is a challenging operation. Uniform coating is paramount to avoid poor construction of the battery and ensure the production of safe, reliable products. Accurate measurement and control on both sides of the substrate ensures raw material savings, improving yield and quality.

These online measurement and control technologies for lithium-ion battery applications include X-ray, beta and laser and can provide results-oriented solutions to reduce costs, improve quality and enhance profitability by helping battery manufacturers meet stringent customer specifications for performance of materials while minimizing raw material waste.

Download the brochure or contact us. Share this article 386SHARESFacebookLinkedinTwitterMail |

【本文地址】

今日新闻 |

推荐新闻 |